What are the reasons for the significant price difference in tracked vehicle transmissions?

What are the reasons for the significant price difference in tracked vehicle transmissions?

Why is there such a big difference in the price of gearbox assemblies for tracked transport vehicles?

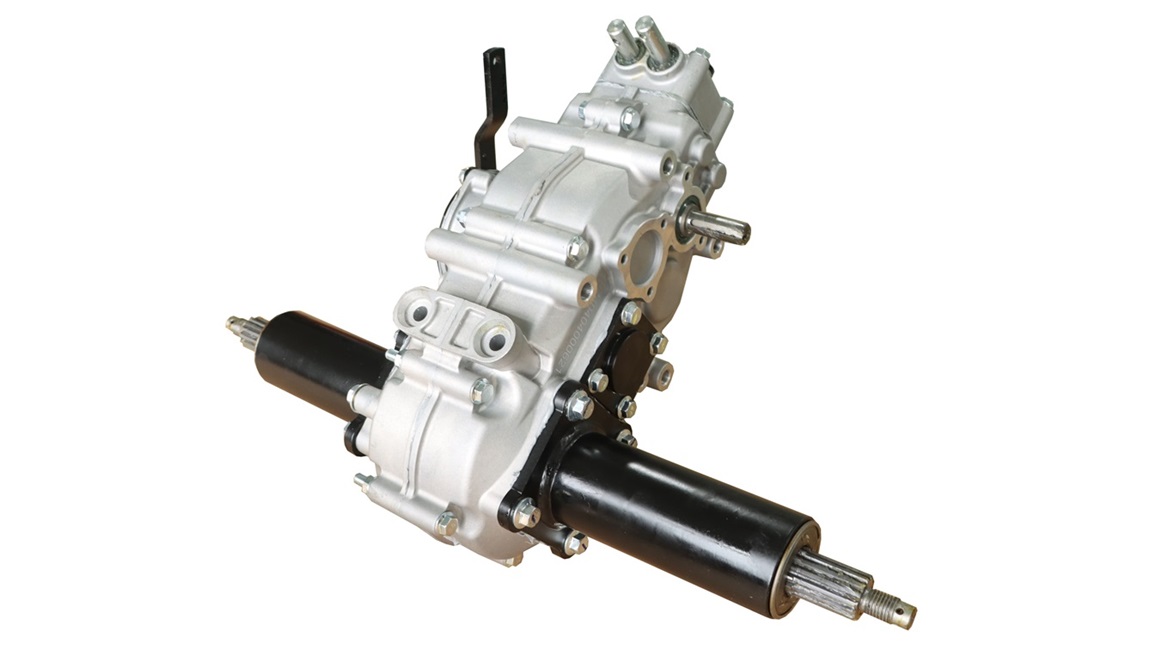

The first question many users ask us about our gearbox is, what is the price difference between your gearbox assembly and other tracked vehicle gearboxes? Today, we will discuss the main reasons for their price difference on several levels to let users know where their money is spent.

Price difference of materials: Many traditional gearbox processing materials use ordinary steel, which does not represent everything; There are also many users who choose gear steel, which has a price difference of many times compared to ordinary steel. Secondly, the price of gear steel of different types also varies.

The difference in machining accuracy: If ordinary machine tools are used for machining process accuracy, the difference may be the difference between several threads. If high-precision machine tools and advanced technicians are used for machining, the error will be between 0.1 threads and 0.5 threads. The cost required for these two can be tens of times different, because if high-precision gears need to be machined, you must use high-precision CNC machine tools to support it, and a high-precision machine tool also needs to be matched with an advanced technician to achieve it.

Welding process differences: There are many gears inside the track gearbox that need to be welded, and the requirements are the thickness and depth of the welding hot melt. If it is only a surface layer, it cannot meet the operational requirements. If a certain welding thickness is required, there are also certain requirements for the welder. This is a very small detail, but in reality, the difference in use is quite large.

Differences in post-processing techniques: After all gears are machined by a lathe, they also need to undergo comparative chamfering in the later stage. The purpose of chamfering is to facilitate smoother gear shifting in the later stage; Heat treatment is used to increase the hardness and wear resistance of the internal gears of the gearbox, which are not present in conventional gearbox assemblies.

The difference in final assembly and simulation testing after assembly: The final assembly of the gearbox must undergo inspection to ensure that each gear meets the assembly and operational requirements. If the assembly requirements are not met, it will directly affect the service life of the gearbox assembly in the later stage; After the final assembly is completed, it is important to conduct simulated gear shifting tests and gear shifting tests, which can quickly and easily determine whether there is a problem with the gearbox as the last line of defense.

The above is a part of the price differences regarding the track gearbox assembly. The above content is based on our own assembly experience to judge. We hope everyone can read it rationally and also look forward to all users being able to buy a suitable orchard gearbox assembly for themselves.